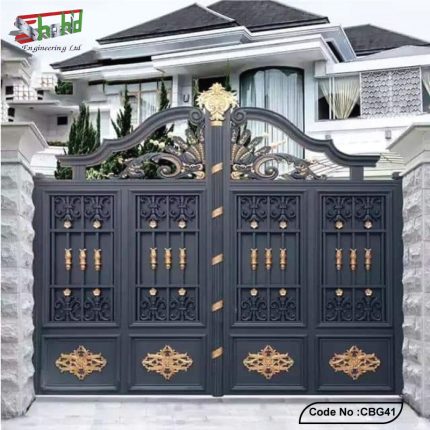

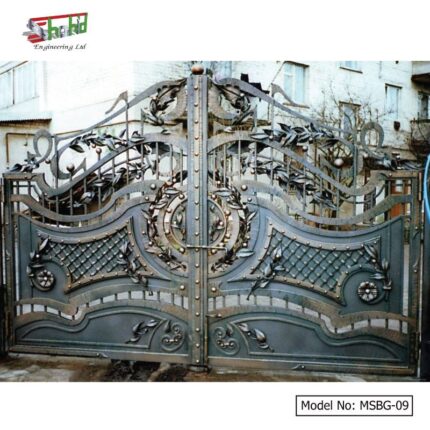

The Casting Boundary Gate is a pivotal component in metal casting operations, designed to regulate the flow of molten metal into molds with unparalleled precision. Crafted from top-quality materials and engineered for durability, this gate ensures optimal casting quality while minimizing defects. With its versatile design and user-friendly features, the Casting Boundary Gate is a cornerstone for enhancing efficiency and productivity in metal casting processes.

Casting Boundary Gate : Key Features:

Precision Flow Control:

- Accurate Regulation: Enables precise control over the flow of molten metal, ensuring consistent and uniform filling of molds.

- Enhanced Quality: Minimizes casting defects such as porosity, misruns, and cold shuts, resulting in superior cast products.

Durable Construction:

- Premium Materials: Crafted from high-grade alloys for exceptional durability and resistance to extreme temperatures.

- Longevity: Built to withstand the rigors of metal casting operations, ensuring long-term reliability.

Versatility:

- Adaptable Design: Available in various sizes and configurations to accommodate different mold designs and casting processes.

- Compatibility: Suitable for use with a wide range of metals including aluminum, steel, iron, and more.

Easy Installation and Maintenance:

- User-Friendly: Simplified installation process with clear instructions, requiring minimal specialized tools.

- Low Maintenance: Designed for easy cleaning and upkeep, minimizing downtime and operational costs.

Casting Boundary Gate | Applications:

The Casting Boundary Gate is suitable for various casting processes, including:

- Sand Casting: Ensuring smooth and controlled filling of sand molds.

- Die Casting: Enhancing precision and reducing defects in high-pressure die casting.

- Investment Casting: Providing accurate flow control for intricate and detailed molds.

- Permanent Mold Casting: Improving efficiency and quality in permanent mold operations.

Casting Boundary Gate | Benefits:

Improved Product Quality:

- Reduces casting defects, ensuring consistent and superior quality cast products.

- Enhances overall efficiency and productivity in metal casting operations.

Cost-Effectiveness:

- Long-lasting durability minimizes the need for frequent replacements.

- Low maintenance requirements reduce operational costs and downtime.

Customer Support:

- Warranty: Standard one-year warranty covering manufacturing defects.

- Technical Assistance: Dedicated support team available for installation guidance and troubleshooting.

- Customization Services: Tailor-made solutions to meet specific casting needs and requirements.

Conclusion:

The Casting Boundary Gate is an essential component for achieving precise flow control and superior casting quality in metal casting operations. With its robust construction, versatile design, and user-friendly features, it’s the ideal choice for enhancing efficiency and productivity in any casting process

Reviews

There are no reviews yet.